Let's Talk

Interested in learning more about what Buckhorn Services has to offer? Please contact us at 985-851-2330 or complete the form below to send us an email.

FIELD MACHINING

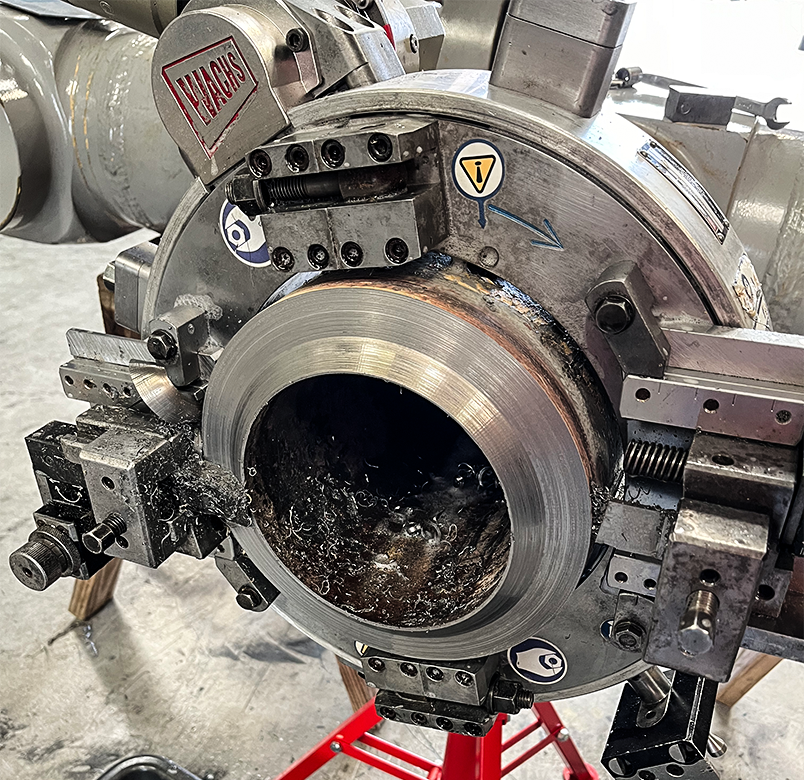

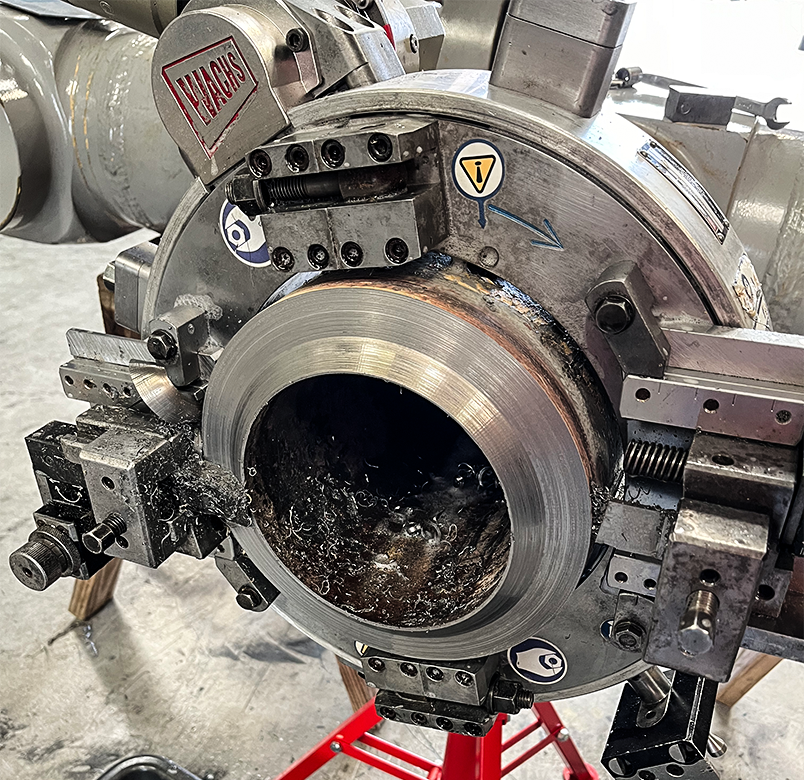

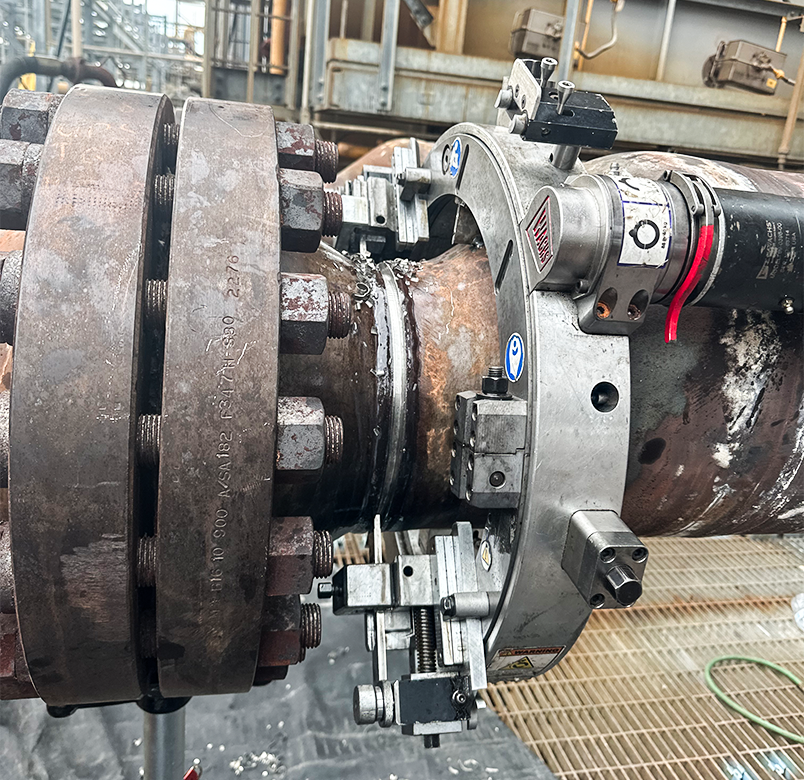

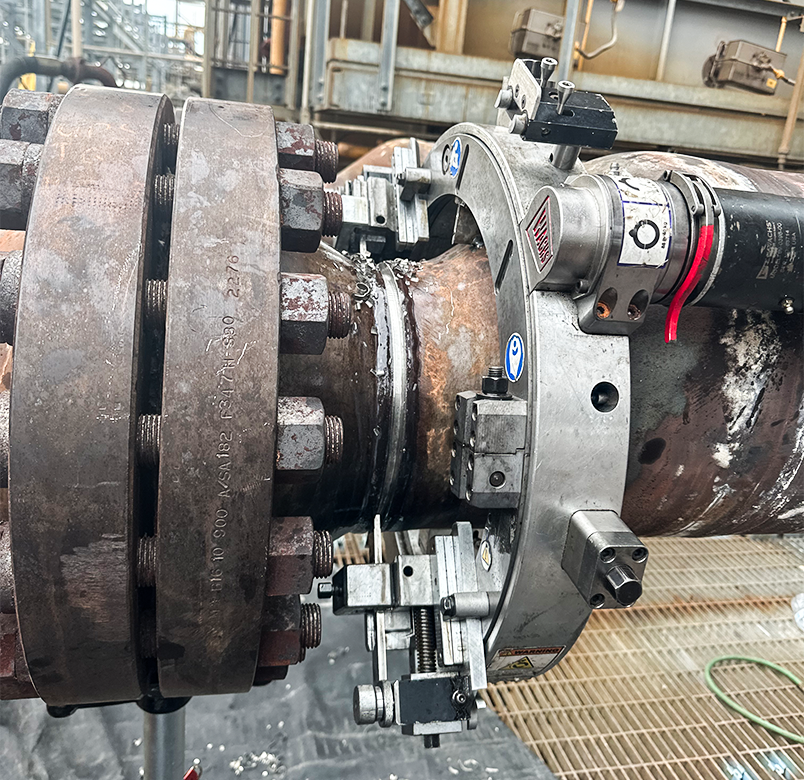

Cold Cutting / Beveling

Buckhorn specializes in cold cut/beveling pipe, which seizes many benefits over conventional on-site machining.

Cold cutting produces no spark or flame to ignite combustible gasses and also can operate with less than 6 inches of radial clearance. The equipment is pneumatically operated and controlled with a remote to provide safety for operators. Exposure to internal contents are also greatly reduced due to the tool only piercing pipe with the last few passes of the tool. The tool is mounted to the outside of the pipe and is a half split frame for easy installation. Cold cutting is ideal for pipe separation and weld prepping.

Projects

Danos – Williams/Discovery Project

Performed over 70 cold cut and bevels and counter bores on X-65 pipe for the reconstruction of the slug catcher during a shut-in. Majority of the cuts were 48" 1-1/8" WT 30 deg bevel.

Excel – CF Industries AM6 Project

Performed 20+ 16" and 28" P-91 stainless cuts with a 37 deg. Pipe with wall thickness greater than 1" were 37-10 deg.

MEI – Mosaic Project

Performed 30+ cold cuts with pipe sizes range 6" – 24", material X-65 to Inconel, wall thickness 1/2" – 2-1/4".

Danos – Williams Markham Tx Project

Performed a DDB isolation with nitrogen purge and cold cut on a 24" pipeline, performed hydrostatic test on the welds, installed gaskets and insulation kits, torqued bolts to Williams specification.

STRIVING TO ACHIEVE EXCELLENCE